The developments of digitalization, and in particular those of Industrie 4.0, are offering manufacturing companies ever more new opportunities to monitor and increase their energy efficiency. With its broad-based testbed at the Production Technology Center (PTZ) Berlin and the domain-specific expertise of its scientists and engineers, Fraunhofer IPK is ideally situated to test and demonstrate solutions for monitoring and raising energy efficiency.

Energy efficiency in cleaning technology with Industrie 4.0

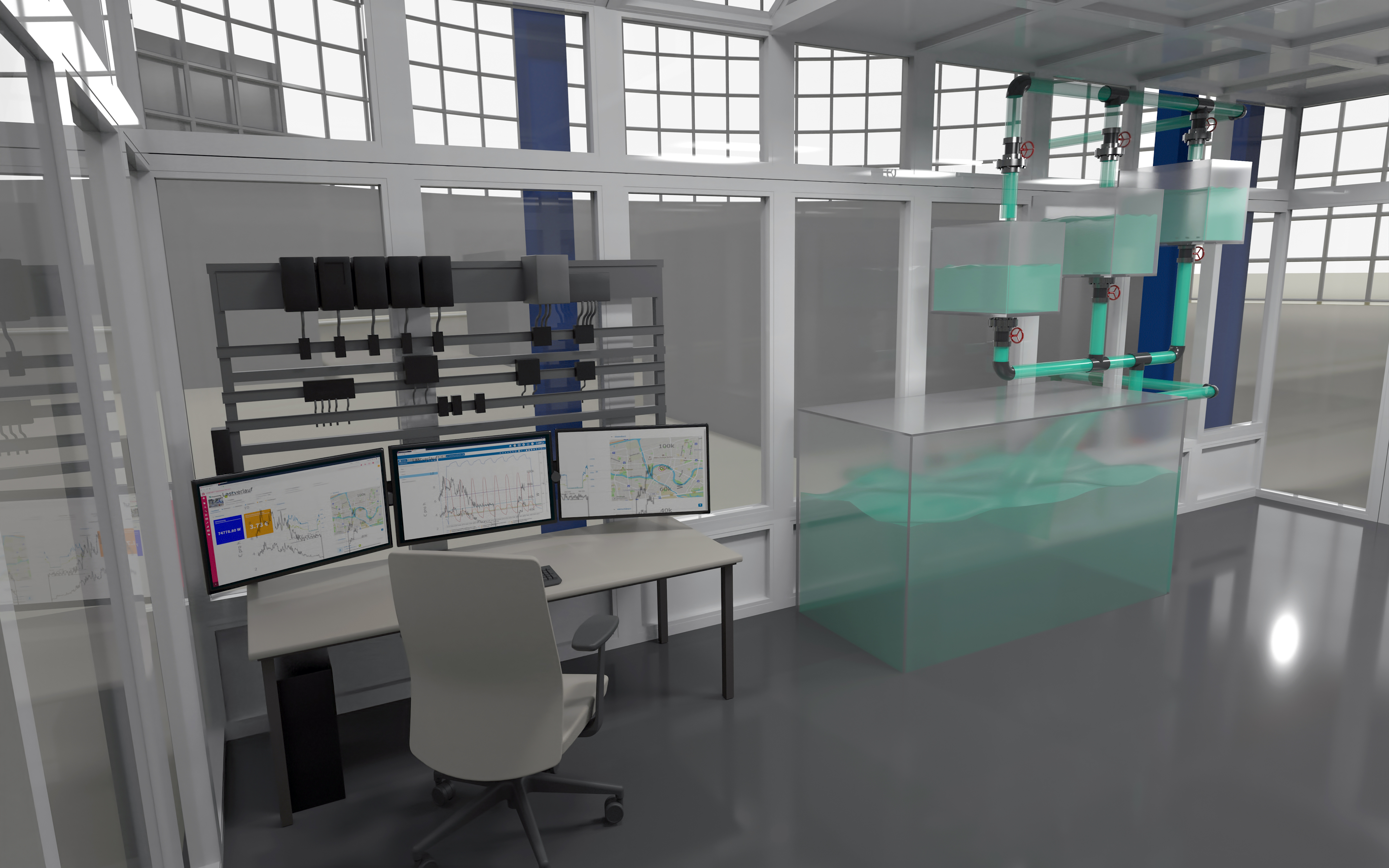

The Lab for Energy Efficiency makes solutions hands-on and tangible

Energy efficiency as an integral aspect of the digital factory

The developments of digitalization, and in particular those of Industrie 4.0, are offering manufacturing companies ever more new opportunities to monitor and increase their energy efficiency. Industry actors have, however, pointed out the lack of a clear overview of practically tested possibilities and solutions for increasing energy efficiency. Users find that many procedures with controlling interventions cannot be directly adopted in running operations, particularly when it comes to serial production. With its broad-based testbed at the Production Technology Center (PTZ) Berlin and the domain-specific expertise of its scientists and engineers, Fraunhofer IPK is ideally situated to test and demonstrate solutions for monitoring and raising energy efficiency.

Living innovation at the Berlin testing field

The cleaning of components is a good example of how individual production steps are closely interlinked and integrated into the overall factory system due to advancing digitalization. The cleaning technology must not only follow the clocked work of series production, but also react flexibly to varying orders. In the background, the supply technology works with large reserves to ensure availability even under extreme conditions. The overproduction and retention of media sometimes holds considerable potential for energy saving. With the help of Artificial Intelligence, supply technology and cleaning processes can cooperate with each other in a foresighted and agile way, which brings ecological and economic advantages.

With the help of an exemplary cleaning process, the possibilities of current and future technologies for industrial cleaning technology will be demonstrated. AI-supported image processing not only detects the components automatically, but also identifies areas to be cleaned. Based on this information, the subsequent cleaning process and parameters are automatically adjusted and controlled. Moreover, the L4EE has an additional focus on production processes. For instance, single aggregates of processing machines can be manipulated with regard to their energy efficiency without endangering the entire manufacturing process. The closer the intervention is to the actual manufacturing process, the more critical integration of automated machines becomes, and the more urgent the need to test it experimentally under real conditions outside of serial production. An interdisciplinary team at Fraunhofer IPK is drawing up the L4EE agenda. Customers are going to be able to take part in open workshops and seminars or in individually arranged consultations and training programs. Visitors to the lab can interactively set scenarios and cause disturbances in the process, thus putting the AI-supported procedures to the test. Is reinforcement learning more suitable for my application than conventional model-based regulation? What information does the operator need? And what skills and knowledge are needed to use current communication and controlling technologies for machine learning?

Authors: Gregor Thiele, Christian Mohnke

Contact: Fraunhofer IPK; Pascalstr. 8-9, 10587 Berlin, www.ipk.fraunhofer.de ; gregor.thiele@ipk.fraunhofer.de , christian.mohnke@ipk.fraunhofer.de

Fraunhofer-Business Area Cleaning

Fraunhofer-Business Area Cleaning